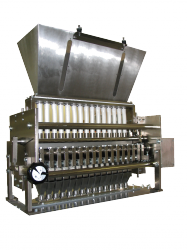

FLAP DOSER ADX

Flap volumetric dosing device ADX is suitable for dispensing loose and granular goods, that is possible to transport into the hopper via feeding conveyor ASV. The advantage of this system is that individual doses are not separated by friction, which allows to dose various abrasive (very dusty) goods or goods whose characteristics may be changed by friction. The packed goods are fed into the doser hopper that through the connecting pipe reaches a position above a middle distribution bar. The front measuring dish is by swinging movement of the feeding pipe filled with goods and back dish is at the same time emptied into a tube. The swinging movement is provided by an asychronus motor with frequency convertor with crank mechanism. This cycle alternates. To set the doses is made toghether for all dishes, even while the packaging machine is running. The hopper has 18 litres capacity and is made of stainless steel. Flap doser is controlled via central computer.

| Maximal output: | 60 cycles/min. |

|---|---|

| Suitable to pack: | Washing powder, sugar caster and crystal, salt, rice, lentils, peas, coffee beans, soluble coffee, poppy seed, compound feed, granules, ground and grate spices |

| Technical drawing: | ABM 15EN + ADX.pdf Note: measurements may vary |