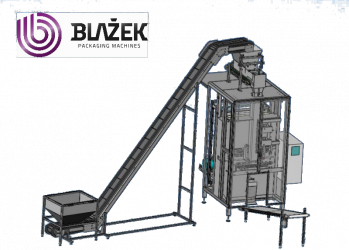

HORIZONTAL AUGER DOSING DEVICE ADS

Horizontal auger doser ADS is designed for smooth and accurate weighing of goods that is fed to the hopper by Z-shaped feeding conveyor, the auger is driven by an asynchronous motor controlled by a frequency inverter. A belt conveyor with dampers and weighing unit ensuring accurate dosing of goods are located inside the hopper. The system is completely lossless, dust-free and closed. The dose can be adjusted from the control panel of packaging machine, the dose can be easily and precisely adjusted even during operation. The dosing device is made of stainless steel materials of non-food nature (in the case of dosing and packaging of food dosing the parts are made of stainless steel AISI 304), hopper capacity is 100 liters. Portion size is determined by the rotational speed and number of rotations of the auger. The advantage of auger doser is its reliability, does not require operator, needs only minimal maintenance, dose adjustment is very simple and is easy to assemble. The doser is suitable for packaging machine ABG.

| Maximal output: | 5-8 doses/min (ADS6), 8-16 doses/min (ADS3) |

|---|---|

| Suitable to pack: | larger amounts – wooden pellets, coal, building and dry mixes, dry colours, flour |

| Dose size: | from 0,5 to 40 kg |

| 3D: | abg3+ads.jpg |

| Technical drawing: | ABG+ADS.jpg Note: measurements may vary |