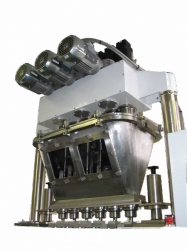

VERTICAL AUGER DOSER ASND

ASND vertical auger dosing equipment is designed for precise volumetric dosing of loose abrasive products. It is possible to transport the product into the hopper by a feeding conveyor ASV. The doser is driven by a servo motor and controlled via a central control system of a packaging machine where the dose can be easily and precisely adjust during operation. The dosing device is made of stainless steel AISI 304 or other approved materials for food contact, hopper capacity is 15 liters. Portion size is determined by the rotational speed and number of the auger rotations. Since the vertical dosing auger passes through the feeding tube (to ensure minimal drop height of products), the minimum diameter of the pipe begins at 25 mm, which corresponds with the minimum bag size of 40 mm. The advantage of auger doser is its reliability, does not require operator and need only minimal maintenance, dose adjustment is very simple and is easy to assemble.

| Maximal output: | 30-40 cycles/min (according to dose size and packed goods type) |

|---|---|

| Suitable to pack: | ground coffee, ground spices, dried dairy products, instant drinks, pudding, flour, icing sugar, plaster, washing powders, dry colours, baby food, glucose, cocoa, cereal drinks, food mixes, instant food, puddings, thickeners, chocolate powder |

| Dose accuracy: | +- 0,2 g |

| 3D: | ASDN vertical auger doser.pdf |